7 Ways To Set Up Corner Fence Post Bracing

A hi-tensile fence is a popular option for livestock fencing due to its durability, low maintenance, and cost-effectiveness. However, a high tensile fence is only strong and long-lasting if installed correctly. One of the critical considerations in installing a hi-tensile fence is properly bracing the corner posts. In this article, we will discuss effective methods to brace corner posts for a high tensile fence, ensuring a robust and secure fence.

Before you begin your corner fence post bracing assembly, it is important to understand the purpose of the posts to begin with. High tensile fence is typically stretched around the perimeter of your farm field, and tensioned tightly so that it remains highly conductive, resistant to sagging, and adequately contains the animals. For this reason, the fence will cause pressure against your fence posts, especially in places where the fence turns roughly 90 degrees (corners). In these places, the pressure of your high tensile fence against the post is much greater, and you will need these posts to have much higher structural integrity. Typically, farmers will choose to use large treated wooden posts, or other strong permanent fence solutions in these locations, and will set up a bracing assembly to give the post additional structural integrity. Without a bracing assembly for your corner posts, the posts will be vulnerable to leaning and structural loss as pressure is concentrated on the corner of your fence assembly. It is therefore very important to ensure strong bracing for your corner post, and to make sure the post is buried deep enough and of adequate dimension. One of the most common problems we run into is ranchers who install corner posts that are too small, or are lacking adequate bracing. Over time, these corner posts will have to be replaced as they lose integrity.

In this post, we will overview different bracing tips, and provide some common guidance for your corner fence assembly.

Steps to corner post assembly

Before you purchase materials for your corner posts, you will need to determine a few things:

1) Determine how many corners you have. For example, if your field fence perimeter is a square, you will have four corners.

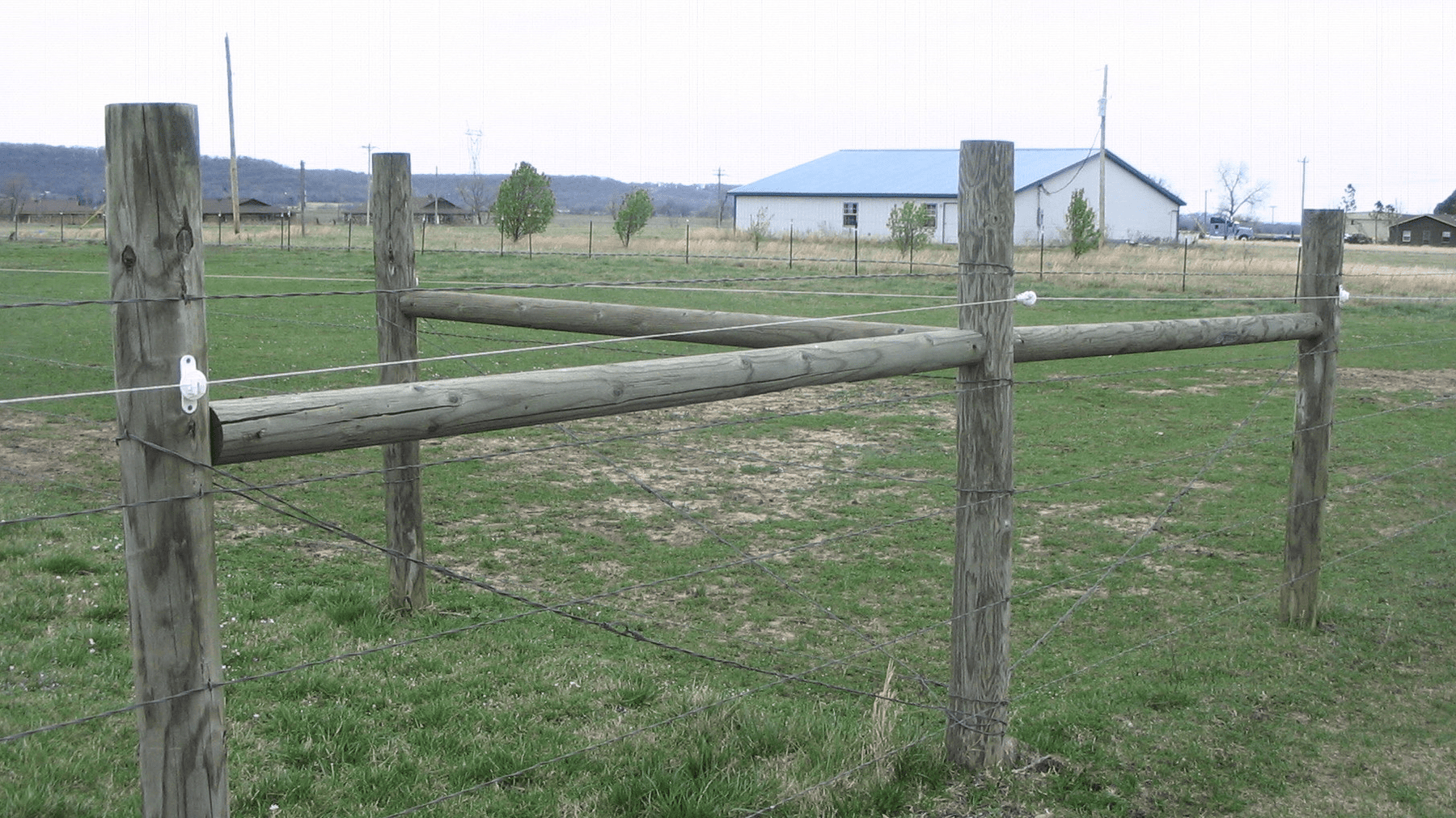

2) Determine how many wood posts you need. If you are assembling H braces, and your field fence has 4 corners, you will need at least 5 wood posts per corner, or 20 total. If, on the other hand, you are doing a floating brace assembly, you will need at least 3 posts per corner, or 12 total. In the case of a floating brace, the diagonal posts can be slightly narrower than your primary vertical post (see below picture).

3) Pick out the correct type of wood or fiberglass post. Most large farm supply stores sell treated fence posts. DO NOT skimp on the quality of your wood fence post, and make sure they are adequately treated. Typically your primary post will be 8 inches or larger in diameter, while diagonal posts in floating brace (dead mans brace) assembly may be 4-6 inches in diameter. Another popular option for corner post assembly is our fiberglass corner post, which provides the diameter and structural integrity of a wood post, but with the durability and rot resistance of fiberglass. This fiberglass corner post is also lighter than wood posts!

4) Dig your holes. The most efficient way to do this is with an auger, though some ranchers choose to install their corner post holes by hand, using a traditional fence post hold digger. Bear in mind this will take much more labor and be much more time intensive. Some ranchers choose to install their corner post holes for their farm fence using a post pounding method. In this method, the rancher uses a hydraulic post driver, attached to a tractor or truck assembly, and directly pounds the post into the ground.

5. Consider how the corner post is grounded. Many ranchers will use gravel, concrete, or QUICKRETE at the bottom of their hole to secure the post. But if you are directly pounding your corner post into the ground using a hydraulic post driver, you will not need to use such a grounding method, as the ground should be compact against your post from the driving action itself.

H-Brace:

This is one of the most common and popular bracing methods because of its sturdiness and reliability. While higher cost than a floating brace, it has slightly more reliable bracing ability. An H-brace is a standard option for bracing corner posts of a high tensile fence. This method uses three posts, two diagonal braces, and a horizontal brace. It also uses a diagonal wire to connect between posts and create triangulation (as pictured). To start, dig a hole at the corner, and insert the first power post. The horizontal brace attaches to the power post, while the two angled diagonal braces attach to the ground on each side. This method is effective and offers excellent stability, making it a preferred choice for many ranchers and farmers.

Floating Brace (Also Known as Deadman Brace):

The floating brace or deadman brace is one of our favorite bracing methods, as it provides a low cost method of bracing that similarly secure and stable as the H brace. It requires less wood posts, less digging, and can provide more than adequate bracing for your high tensile fence. A post is driven into the ground, and 2 diagonal posts are attached to it, "floating" at their ends on concrete, cinder blocks, or rocks. A wire is then attached from the bottom of each diagonal post, back to the base of the primary post (as pictured). View our related guide on how to build a floating brace assembly.

Rock Pinning:

Rock pinning is a method that requires installing rocks or boulders around the corner fence post while also using traditional bracing methods. This technique is useful when the soil is too shallow or not strong enough to support the corner post. The rocks provide added weight, while the bracing helps secure the corner post. It would be best if you consulted with your local fence expert to ensure the correct approach in doing this.

Guy Wire Brace:

The Guy Wire brace is a method often used for telephone poles and other industrial fence assemblies. Guy wire braces use wires extending from the post to anchors in the ground. This method is useful if you do not have enough space for traditional bracing. Guy wire braces are ideal for steep slopes where anchors can be installed up against the hillside and braces attached to the corner post. This approach is also effective in areas where it's not feasible to use traditional bracing methods. Read more about this type of bracing here.

Leave a comment