9 Tips & Tricks For High Tensile Fence Setup

Are you looking for tips and tricks to help you set up a high tensile fence? High tensile fencing is a great way to keep animals in and predators out, and our electric high tensile fence provides extra predator control for rotational grazers and regenerative farmers looking to set up secure field fencing. It is also a cost-effective way to keep your animals safe and secure. In this article, we will provide you with 9 tips and tricks to help you set up a high tensile fence, along with general recommendations for your field fence that will be helpful in your electric high tensile fence setup. We will discuss the importance of proper installation, the materials you will need, and the steps you should take to ensure your fence is secure. We will also provide you with some helpful tips on how to maintain your field fence and keep it in good condition. By following these tips and tricks, you can ensure that your high tensile fence is properly installed and will last for years to come.

TIPS & TRICKS for high tensile fence setup

1. Choose the right type of fence for your needs. High tensile fencing is a great option for containing livestock, but it is important to select the right type for your particular situation. Single strand high tensile fencing can be adequate for containing certain types of livestock, such as cows, while more robust system live high tensile woven wire may be helpful for containing other types of livestock like sheep or goats. If you go with single strand, consider the number of single strands that are required for your livestock type, and consider the risk of predation. Some clever predators can navigate their way through single strand fencing, even if it is adequate for containing your animals. Electrifying a single strand system is required, while woven wire can sometimes be utilized without electricity and still be marginally beneficial for anti-predation. Most grazers using non-electric woven wire high tensile fence will use barbed wire at the top and bottom of the fence, and/or a single strand of electric at the top and bottom of the fence to prevent predators from digging or climbing the fence.

-Electric Single Strand High Tensile

-Electric Woven Wire High Tensile

-Non-Electric Woven Wire High Tensile

2. Install the posts. Regular line posts should be spaced 8-12 feet apart and driven into the ground at least 2 feet deep. Because high tensile is generally stretched to be tight, you will also need to have a solid corner post setup wherever there is a sharp turn in your fencing system. If your pasture is a square, for example, you will need to have at least 4 corner posts in order to support your fence tension for a fence with 4+ 90 degree turns. Generally you will stretch your field fence from corner to corner, in individual sections, rather than stretching your fence all the way around your pasture without stopping. These individual sections are then connected with jumper cables. It is much easier and more secure to set up a fence section by section, which improves rigidity of your field fence, and allows you to address maintenance and repair needs on a section by section basis.

When it comes to pickling posts that go between corner posts, you should pick a permanent solution that is resistant to weather and has adequate strength to support your fence. Our fiberglass fence posts are a popular choice, but there are other choices like polycarbonate or plastic. With that said, Powerflex fiberglass fence posts tend to offer the most competitive and durable option on the market.

3. Prepare the insulators. Insulators should be placed on the posts at regular intervals to prevent the wire from shorting out. For corner posts, make sure your insulators are cut long enough so that the high tensile wire will not end up rubbing against the post.

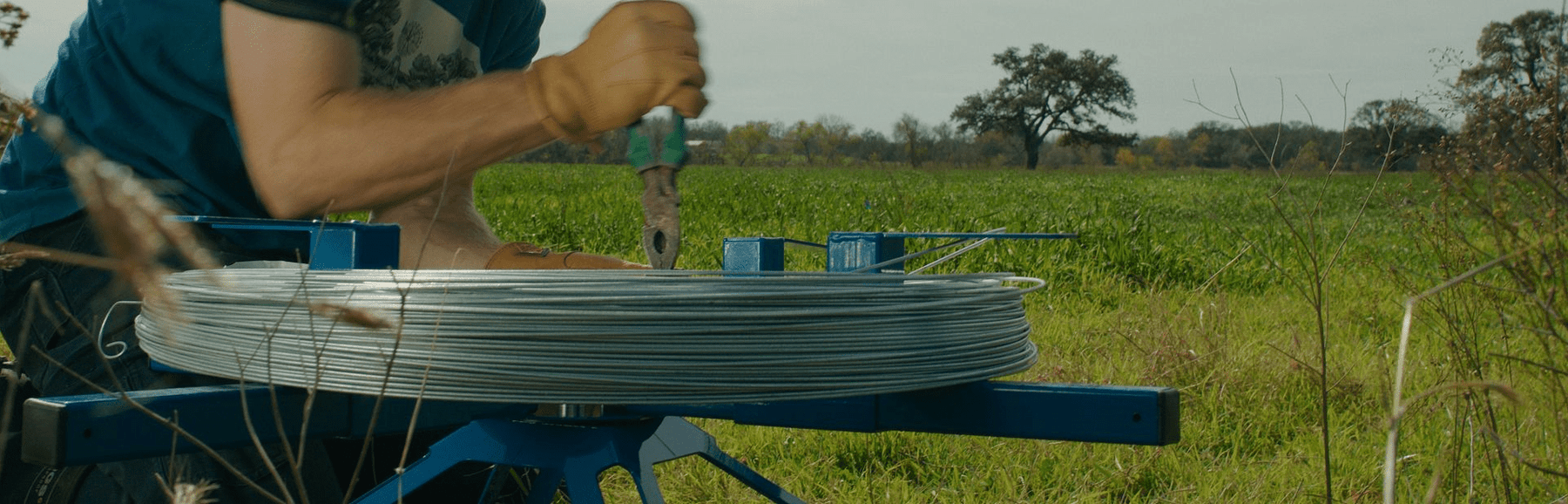

4. Roll out the wire. High tensile wire should be attached to the posts using a spinning jenny, as manually rolling our high tensile wire can be quite tedious. If you are rolling out our woven wire fence, you will need to either use a ATV, or be patient in rolling it out manually. Using a guidewire, a line that runs the perimeter of your fence to guide you as you roll out the fence, can be quite helpful.

5. Secure the wire. Make sure the wire is securely attached to the posts for each section. Each high tensile wire section will be tied to each corner post by using insulators. Without first extending the wire through post insulators, your corner post will end up grounding your fence (unless it is a fiberglass corner post). A popular technique for connecting high tensile wire to a corner post is to extend it through an insulator, then tie the high tensile wire to itself using a slip knot technique.

6. Make the jumps. End post/corner post in your field fence will represent a short in your fencing system. The entire perimeter of your fence needs to act as a circuit, meaning every section much connect to another. At every corner post/end post location, you can secure multiple jumper cables which will allow the conductivity to pass from section to section. You can use nuts or tie techniques to connect the jumpers to each section.

7. Install the gates. Gates should be installed at the appropriate locations along the fence line. Again, you will need to maintain a circuit even at these gate sections. To do this you will need to create a jump using a underground conduit wire. Dig a trench in front of the gate, and connect the fence sections by connecting them underground, again using nuts or tie techniques.

8. Check the tension. Make sure the wire is properly tensioned. Gripples and the gripple tool can make tensioning a high tensile wire fence easy. Just connect the gripple to the high tensil wire, then connect your gripple tool and tension it that way.

9. Test the fence. Test the fence by using a fence tester, then run a few animals through it to make sure it is secure.

Other Frequently Asked High Tensile Fence Questions

How tight does the high tensile wire fence need to be?

Hi-tensile wire needs only between 150 to 200 pounds of tension. If you're used to putting up barbed wire, then you would normally put about 300 to 350 pounds of tension on it. So, don't over tension hi-tensile wire. Powerflex fence is electrified, and so the tension is not the primary property that will keep predators out or livestock in. You can always check tension and improve tension after the fence is set up.

How often do I need to trim weeds or branches around my high tensile fence?

Because the fence is electric, it should keep weeds "burnt" down and prevent the weeds from overwhelming the fence. Make sure to keep your energizer plugged in so that weeds do not overwhelm the fence. It is a good practice to check your fence perimeter a few times a year to make sure there are no overhanging limbs, and to occasionally trim weeds as they encroach on your fence and lower the voltage of your electric fence system.

Is my high tensile electric fence dangerous to people?

Electric fences send pulses of voltage through the wire, and are not likely to harm people, pets, or wildlife. Because the actual amp value is low, the fence is unlikely to cause injury or death to a human. Because the voltage is high but the amps are low, you will not actually end up with much electricity flowing through you when you touch the fence. With this said, it is important to keep a few safety factors in mind. 1) Hang warning signs on your fence 2) Be cautious when bending down to the fence, keep your head away from the fence 3) Keep children away from the fence

How strong does my energizer need to be to electrify my high tensile fence?

At Powerflex Fence we have been proponents of buying and using larger energizers. It is not uncommon (depending on fence load) to drop from 10,000 volts in March to 5 or 6,000 volts in early June. Thats OK! But, on the other hand, if you go from 5,000 volts down to 2,500 volts – youre going to have a problem. We get a lot of calls regarding this scenario. If you are using a voltmeter with a fault finder or fence compass, sometimes you get nervous about readings of 20 to 40 amps. Consider buying energizers with a output joule rating well above your requirements. We encourage you to call our office if you have questions about what energizer is best to choose.

How much should I ground my electric fence?

You should install at least 2 or 3 times the amount of grounding rods you think you need, and you should drive them as deep as possible into the ground. The most common issue we run into with new fence installers is that they have not adequately grounded their system. Install multiple grounding rods and link them together. It is not possible to over-ground, but it is very possible to under-ground.

Helpful Videos

These are videos that reference Powerflex fence setup and help give you some guidance on fence setup. We do not own this content.

Related Newsletter Readings

Related How-To Content

Overview of electric fencing

Basics of building a high tensile fence

How to build a floating brace assembly for corner fence

Grounding the energizer

Post and Fence Assembly

Common Tools for High Tensile

A Picture Guide on Building a High Tensile Fence

Electrified Woven Wire Guide

High Tensile Wire Do's and Don'ts

Understanding Insulated Wire and Undeground Cable/Conduit for High Tensile Fencing

Conclusion

By following these tips, you can ensure that your high tensile fence is properly installed and functioning correctly. By using the right type of underground conduit wire, you can ensure that your fence is safe and secure.

Setting up a high tensile fence can be a daunting task, but with the right knowledge and tools, it can be done quickly and easily. By following the 9 tips and tricks outlined in this article, you can ensure that your fence is set up correctly and securely, and that it will last for years to come. With the right preparation and attention to detail, you can have a high tensile fence that will provide you with years of reliable service.

Leave a comment